Rubber Moulded Product Range

Vulcanized Frames for Façade & Curtain Walls | Rubber Orings | Rubber Isolation Pads | Rubber Grommets | Molding Corner Joints

Rubber O-ring | Rubber Grommets

O Rings When assembled between two or more parts, an O-ring, also referred to as a toric seal, is a loop of elastomer with a

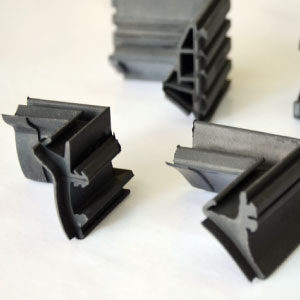

Vulcanized Corner Joints / Molded Corner

Calor Pyro Rubber provide a fantastic corner offering effective thermal insulation and sealing against water and dust seepage to reduce the cost of air conditioning.

Vulcanized Frames for Façade & Curtain Walls

Using transfer moulding processes, the corners are molded and the profile ends are joined to create a full gasket frame. This procedure involves extruding the

Rubber molding involves transferring, compressing, or injecting raw rubber material into a metal mold cavity in order to transform uncured rubber or an elastomer into a usable product or shape. Injection molding, compression molding, and transfer molding are among the most common methods.

Manufacturers have been able to produce a wide range of moulded rubber products through the injection molding of rubber materials, including silicone, neoprene, nitrile and EPDM. CALORPYRO® is molded rubber products manufacturers having latest technology in molding process.

- Rubber Grommets

- Molding Corners

- Vulcanized Frames for Façade & Curtain Walls

- Rubber Orings

- Rubber Isolation Pads

Product Gallery for Rubber Moulded